services details

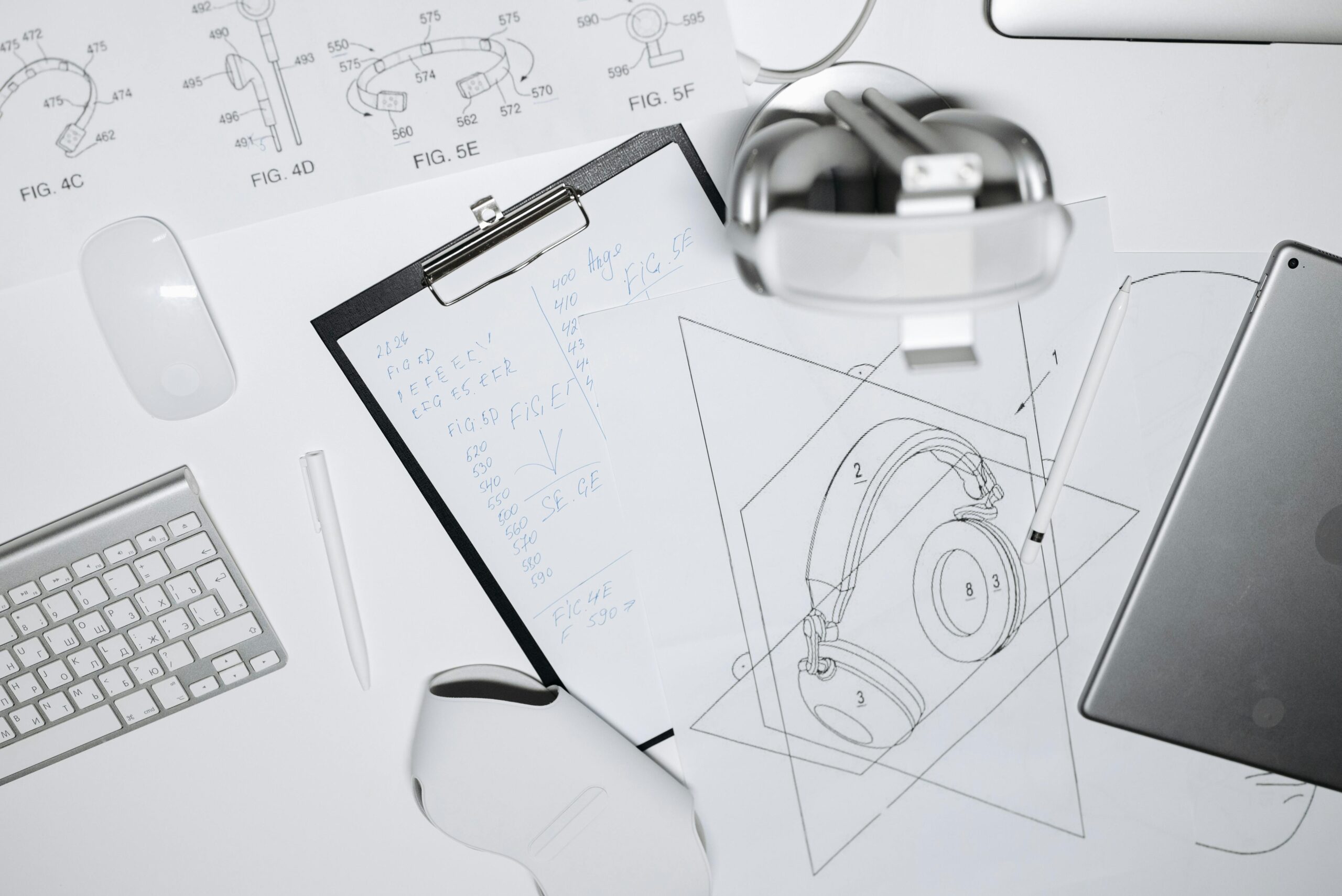

Product Design & Development

Rigorous research, design study, detail engineering, prototyping, and testing.

We provide insightful product design services with experience of more than a decade.

Our insightful product design services experience of more than a decade helps us assist product design and development firms looking for fast pace development of their most complex sheet metal components or machinery. Our product design services team has developed world-class products for our customers that involve rigorous research, design study, detail engineering, prototyping, and testing.

We can manage an entire development program from receipt of the design concepts, through design engineering and data production, to tool design, mold-flow analysis and onwards to prototyping, using some of the most experienced engineers. Whether it’s a project emanating from the automotive industry, or the medical sector, involving transport or aerospace projects, or consumer products and special effects, Thinkdesk can make a valuable contribution to the business.

Our engineers have experience in designing hydraulic, pneumatic and manual jigs and fixtures.

- Welding Fixture Design

- Testing Fixture Design

- Machining Fixture Design

When it comes to machine design we are not limited to only one kind. Due to their vast experience, our engineers are capable to accomplish design for, basically, everything starting from individual pieces of equipment to larger machines and complex systems used in different sectors.

We provide plastic mold design services that utilize a number of advanced molding processes. Let it be single or multi cavity mold, we design mold for best product outcome. Our high-end CAD & CAE tools ensure your design is validated for better output.

Some of the key sheet metal product design includes Catwalks, Enclosures, Data center racks, Doors, Cabinets and many custom-made products.

Our product development and engineering service consists of consultation, design-for-manufacturability, full product development and design, building, prototyping, volume manufacturing, comprehensive project management, and reverse engineering design.

3D models of photo-realistic quality can supplant actual photographs of real objects and scenes, and in some cases these images are all that’s required to make a professional judgment about a new product. Clients occasionally augment the physical modelling process with virtual prototypes.

The casting design and manufacturing team have designed and manufactured complex shapes for several global customers with the aid of the latest casting software tools and casting technologies. The cast products delivered by our team are being used in industries like Heavy Engineering, Aviation and Automotive among others.

The process of duplicating an existing component, subassembly, or product, without the aid of drawings, documentation. Our experience engineers understand product, its functioning and manufacturing process and then do Reverse Engineer the product.

Frequently asked question

- Hourly- rates are available, based on your volume of work and type of work

- Full-time Equivalent – rates can be provided for larger projects, ensuring your project will be completed within a fixed budget.

- Refer outsourcing model for more details.

Being ISO/IEC 27001 Certified:

- Think Form Systematically examine the customer’s information security risks, taking account of the threats, vulnerabilities, and impacts.

- Design and implement a coherent and comprehensive suite of information security controls and adopt an overarching management process to ensure that the information security controls continue to meet the customers’ information security needs on an ongoing basis.

Standards and methodologies for project management quality assurance

Effective processes to support arrangements for good governance and accountability;

Input from individuals with the appropriate subject or technical expertise to ensure the development of outputs that are fit for the purpose.

Need an appointment

If you need help with anything related to design than don't hesitate to get in touch with us. We are always here, to help you out.

Company

- Our Team

- Our Values

- Our Mission

- Our Expertise

- Our Locations

We provide really great services & solutions in design.

Subscribe to our newsletter & get news related to design.